I have lost count of how many times I have had business leaders ask where do I start when it comes to circular economy in my business. There are five principles you need to commit to and master if you want to create a competitive edge with circular economy and create a positive environmental impact: Mindset, Mission, Pathway, Implement, Communicate. And in that order.

If you can’t honestly tick all five boxes, then this is your job for the next 6 months. Follow through and you will get results!

This is the third out of five articles where I introduce each of the principles, so you can accelerate your journey, get success and impact the world in a positive way.

Will be happy to answer questions along the way.

Circular Business Success, part III – Pathway

Now you know where you want to go in the long term. The question is where to start and how to get there. What is the strategic approach and priority and what is the right pace for you to move ahead? I have created a method for you that will guide you to handle exactly this challenge. I call it the “Pathfinder” and it is three steps each with its tools and processes.

Step 1) Map out potentials

By now you should see and believe that circular economy can offer business value for you. But what kind of initiatives could I set in motion? Where are the potentials for me in the circular economy? There are several ways to go about this, but I find this following mapping exercise really impactful and fairly easy to get started on at this stage where – your work on the principles “Mindset” and “Mission” has given you the basic understanding you need.

There are five disciplines within the circular economy, each with its focus, potentials, and characteristics.

- Stable supply of resources

- Waste = resources

- Product life extension

- Increase utilization

- Product as a service

I will unfold them a bit below and there is also a link to brief (3 min ish) explanatory videos for all five.

The process

You can do the exercise alone, but I highly recommend you gather a few colleagues with insight into your processes and material flow. Then you go through each of the five disciplines and brainstorm on all the places where you can see you might be able to find a better solution. Write down as many ideas and initiatives as you possibly can for each of the five.

Then write down a list of the top 5-10 pain points that you have in your business and that your ideal customer has. With that in mind go through the five disciplines again to see if you now spot additional ideas and potentials.

In the end, this will give you a complete map of all the places you currently can see you could use circular economy to improve your business and your impact on the world. This is the foundation for step 3

The five disciplines

#1 Stable supply of resources

The essence here is to ensure that you have long-term stability in your supply chain and the supplies of resources that you need. Companies that focus here tend to have a large consumption of materials or have some component in the product that is really, really critical to the quality of your products. The focus here is to go from non-renewable resources to renewable resources. And in most cases, at the same time, it is also a shift to healthier materials. The reason why they do this is to avoid the fluctuations in prices and availability then that they either already see or that they can foresee will come in the years ahead

Bear in mind that this is basically a substitution process and as with all other kinds of material substitutions in your product chain it demands a lot of knowledge, and it is imperative that you collaborate well, and can take leadership of the supply chain dialogue as this is a co-creation process in most cases. Moreover, it will likely demand investments to get the kind of results that you would like.

Some support questions to ask yourself:

- Can the availability of raw materials restrict my growth in the future?

- Will customers continue to accept the key materials we use?

- What alternative materials could we use and what additional value could they create?

- What business benefits would a shift from non-renewable to renewable materials give us?

- What risks does business as usual constitute for us?

Click here if you would like a brief explanatory video of this discipline.

#2 Waste = resources

The second discipline we call “waste equals resources”. This is what most people think about when they think of circular economy. Focus is on whatever leftover materials or waste or byproducts that you have in your production. And instead of viewing it as waste to get rid of, perhaps even at a cost, you view this as a resource. A resource that you or someone else would find valuable and can use. It may stem from a product that does not pass your quality control or you may simply produce collateral material as part of the manufacturing process – e.g., you have a wooden or plastic material that enters your factory in squares and the product you produce is round. So, there will inevitably be corners. You can have all kinds of leftover materials and it is not necessarily because you don’t have an efficient production setup, but simply that it’s unavoidable that you have something left over. But you can take that material and instead of considering waste, view it as resources that need a new direction. Remember that waste is a manmade concept. Nowhere in nature do you will find waste. Everything is a resource for something. Take that approach and ask yourself: “What could I use this for?” Or “who could use this” or “what would it take for somebody to use this?” In some companies, it is re-used in-house by looping it back earlier on in the manufacturing process. Another example of use is what is often referred to as symbiosis, where you buy or sell leftover materials between companies so one companies leftover becomes a raw material for somebody else. Others again take back their products and close the loop themselves and can reuse the product or the materials in the product somehow.

It is particularly relevant for you if you have large quantities of byproducts or leftover materials today, and if you have products with very long-lasting materials with shorter use cycles. If you are looking into closing a loop yourself it will be an advantage if you have control over production as well as the actual point of sale.

Some support questions to ask yourself:

- How much money do we spend on waste handling?

- How many tons of raw materials ends as waste instead of a finished product we sell? How much money has it roughly cost us to buy these materials that we never utilize into products?

- Why are they not utilized today? Can we optimize to reduce the overall amount of wasted resources?

- What would it take for them to become valuable resources again? If not in our production, then who might find them useful and valuable?

Click here if you would like a brief explanatory video of this discipline.

Product life extension

The third discipline is called “product life extension”. This is where you take a product that is already in use and instead of throwing it out at the end of that service life, you take it back and upgrade it somehow and thus give it a new service life. It is the “RE-everything” – re-manufacture, re-purpose, re-design, etc. You can do it with your products, or you can build a business around giving someone else’s used product a new life and putting it back into the marketplace.

Often it revolves around giving the product a new look or a new price or around offering it to a new market or to new users. Numerous examples show you just need a fraction of the money, time, energy, and materials to upgrade an existing product to become valuable and put it back in the marketplace.

It is particularly relevant for you if you have products built on materials with a long lifetime; or if you are working in a sector where there is a really high speed of change, and thus a fast turnover of products. This is more prevalent in sectors where customers perceive the product to be redundant and purchase a new version way before the product is actually used up or loses functionality – before it has come to its actual end-of-life.

Do bear in mind that it does require a change in either incentive structures or concepts around actually getting your hands on the product that’s already out in the market or perhaps even in new business models. But it is known technology and products you’re working with and that makes it slightly easier for many as they are and familiar ground.

Some support questions to ask yourself:

- Do we have products where the perceived value amongst our customers suddenly drops without a corresponding drop in material value?

- What would it take to upgrade these products to become fully functional again?

- Who would find them valuable – either in the same segment or another segment or geography?

- Do you produce components that can upgrade some other products? What could you upgrade that today is thrown out?

Click here if you would like a brief explanatory video of this discipline.

Increased utilization

The fourth discipline, it’s called “increased utilization”. This is where you take existing products and maximize their utilization of them. You can potentially do this for all products that have idle time, and there are lots and lots and lots of stuff around us that we produce, but that we far from use at its capacity. Thus, there are lots of business opportunities and lots of opportunities to deliver the same output with fewer products.

The discipline is also referred to as the sharing economy because you share a product between several users. But the core thing here is to increase the utilization of existing products. And it is done in many ways. Some set it up as an old fashion way of just sharing stuff as you do with your neighbors either with or without money involved. Others set up a company that has ownership of the products and invite a larger group of people to use them. Again, with or without payment. We also meet this model in action with production equipment and with logistics equipment.

So, if you think it is only about B2C you are missing the point – there is more than Airbnb and Uber to this discipline.

It is particularly relevant for you if you have access to a large volume of products that have idle time. Or if you are engaged with products with a very long lifetime, but shorter use cycles. E.g., a hand drill, a car, special production equipment, or excess storage capacity in your warehouse. Everything that is used for a shorter period, or perhaps just once or twice, but where the product can actually live a lot longer. If you could share that between several users, it will increase the revenue each product can drive as fewer products would be needed to deliver the same kind of results.

Bear in mind that this will just about always demand new business models. It is platform-driven and tech demanding – data is the glue here. It does require new partnerships and new value chains in most cases. So there’s a bit of work necessary to get this done but there are also a lot of opportunities because the products are already out there.

Some support questions to ask yourself:

- How high is the utilization degree on our main products?

- Is our product suited for sharing in terms of the typical use scenario?

- Do I see products around me with a significant idle time that we might be able to utilize better through our competencies, access to market, position, etc.?

- Is there any excess capacity in transportation or elsewhere in the value chain that we can take part in utilizing better?

- Is there any excess production capacity in our factory or elsewhere, that we can take part in utilizing better?

- What shared services could we offer our employees, partners, community, and clients that would create additional value?

Click here if you would like a brief explanatory video of this discipline.

Product as a service

The fifth and final discipline here is “product as a service”. Here the focus is on the essence at the core of your product. On the value – the functionality of the product? That is what people are interested in. So instead of selling the product, you sell the service, the result, the value that it provides. This means that you as the producer, maintain the ownership and thereby also the risk of the product in the use phase.

You would want to build different services on top of your product to make sure that the product delivers optimum performance and that your customer gets the best experience. The implication is a shift away from selling to offering your product in leasing, buyback programs, and subscriptions.

It is particularly relevant for you if have high-quality products with a long lifespan and a solid business. Please note that this is not the easiest of the disciplines to get started with when you have an existing business. It does demand that you have a pretty solid business and quality products. And you do need a fair level of capacity for change and development in your organization, including yourself as a leader as demands innovation both in terms of the products, the processes, the finance the business models, and your service models. So, there are a lot of things you need to reconfigure and develop and bear in mind that shifting sales to a service model will change your cash flow with all the implications that this has. Also, remember that such a move will change the sales process and you need to make sure that your market is actually ready to change and no longer buy the product and own it but just access the service that’s needed.

These are the five disciplines. Go through each of them and map out where you could see this potentially could impact your business and impact the results that you can create both in terms of money and environmental impact.

Some support questions to ask yourself:

- What opportunities could arise if we maintained the ownership of the product and thus also the contact to the customer?

- How would not owning the product make it easier for our customers?

- What additional services could we put on top of our product that would increase the value of the product?

- What value could we get out of our used products once we get them back?

- How much longer would it be possible for us to make the service life of a product?

Click here if you would like a brief explanatory video of this discipline.

Step 2) Self assess your level of maturity

The right next steps for you are also defined by the level of maturity (level of experience) you have in working with circular economy in your organization. You might ask, “well why is that important?” It is critical because if you set yourself up for steps that are either too advanced or simple, then you set yourself up to fail. Simply because such steps will not match your organization and the people in the organization. Let me give you a reassembling example. Let’s say you want to increase your marketing effort and you look out in the world to see who is really, really successful and really, really good at marketing. And you might say, “Hey, Apple, they’re great at marketing – let me copy their approach.”

But if you try to copy Apple’s approach to marketing, I can almost guarantee you that you’re going to fail, because you probably haven’t spent billions of dollars in creating the platform, the brand, and the fan base that Apple has. Because they have worked with their marketing extensively for years, they are now masters of it – they are a very mature organization when it comes to mastering their brand. So, you cannot copy their strategy and expect success. You have got to make sure you choose an approach that matches the level you are on. The same goes for your work with integrating circular economy in your business. You have got to make sure that you start where you are and move ahead from there. And you have to move at the right pace and take the right steps moving forward.

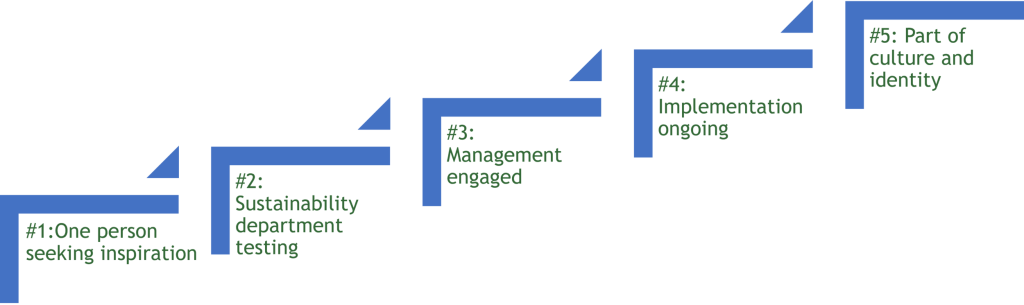

This realization made me create what I call the maturity staircase some years ago. Over the years, I have seen literally hundreds and hundreds of different companies and the way they work with integrating circular economy into their business. And what I see is that you can distill five different levels of maturity – see illustration below.

The first level is the basic level. This is what you could call a one-man-band. Here you will typically find that the person responsible for sustainability (whatever the title may be), is seeking insights. She/he is trying to find inspiration. And nobody else is really involved. Thus, it is a pretty basic level of maturity, as there is only one person involved. It could be that this person has quite a lot of knowledge about circular economy, but since there is only one person engaged in it, there’s quite some distance to go until it becomes something that will impact the business and change the way they operate.

If you are at level one what you need is to build capacity to master the circular economy in a business context and you need to find examples of how similar companies are approaching circularity. Thus, initiatives like building competence in the organization, field trips, and internal discussions about what kind of value circular economy could bring to your business would fit right in as part of year one in your roadmap. I would highly recommend that you do not make this step too comprehensive as you can spend years here without creating real impact – just getting ready. Get some basic knowledge and understanding in place and then start experimenting. It is “I need to do to know” – not “I get to know to be able to do”.

Level two is where you can see that whatever is going on in terms of circular economy, is driven entirely by the people in the environmental department (or corresponding if your company is smaller). Typically, this is where you see that pilot projects are going on. Either initiated or decided or ongoing or perhaps there has have even been a couple of those. At this stage, the environmental department is aiming to learn more and gain some experience through pilot projects, but so far there is no real involvement or commitment from the rest of the organization.

If you are at level two it is about dipping your toes in the water and testing out a few things. This approach is chosen partly because the environmental department doesn’t have a commitment from the executive level and thus only can deal with whatever is within their reach, and partly to gain some experience in an area of lesser importance for the business.

At level three you are starting to see management engage at a strategic level – the CEO or some other at the executive level is engaged. You will start to find vision/missions/ambition statements and some sort of strategy or idea about what to focus on. It’s still a very basic project. We may still only have pilot projects, but now it’s getting an overall direction towards where is it that they want to go. This is becoming a strategic issue.

If you are at level three, get clarity about where you ultimately want to go. Organize your strategy by considering your fundamental focus and seriously connect it to your business. It’s also essential to make sure the whole management team is on board and has the needed competencies to integrate the circular business approach. These are typical tasks to include in the first steps of your roadmap.

In a level four organization, you will find clarity about where they are heading and why and there is a strategy that ties into the business strategy to some degree. You might also find some sort of roadmap for where you’re going and basically that several initiatives are going. You will see circular initiatives start to show up in specific parts of the production of the products. Often in form of an eco-line/eco-friendly line/green line/sustainable line in the product portfolio. All in all, you can say, that implementation has started. As a consequence, you are starting to see that a lot of different areas are engaging. It can be product development, perhaps sales, manufacturing units, or similar.

If you are at level four the focus could be on the implementation of specific initiatives on developing answers to business problems. Continued effort to spread the word internally as well as outside is another focus for this level and for many companies supply chain dialogues and collaboration start to become increasingly important.

In level five organizations you will say that circular approach is a part of the culture and a part of the structure. Everything is in place – it is getting ingrained in the DNA and identity – this is who we are. In a level five company, you will find that sustainability and circular economy is everywhere. It is how we do and think, and everything is being aligned and integrated into it. It’s become part of their natural way of going about it.

So those are the five levels of maturity, and the question is where do you fit in? Assess yourself and really be honest, there is no reason to try to fake it here. You will only discourage yourself and your journey ahead. So be brutally honest with yourself and mark yourself on the scale and then continue to step 2.

- Are you at level one where just one person is trying to push this and nobody else is really engaged?

- Are you at level two where this is an environmental department initiative?

- Are you at level three where the leadership team is engaged?

- Are you at level four where you are starting to implement the strategy and several units in the organization are engaged?

- Are you at level five where it is ingrained in your culture and everything you do?

Step 3) Decide on the next steps

Now you should have clarity around which of the five disciplines you see the biggest potential within. The next step is to dive in and brainstorm all the ideas for potential steps to take within the one-two disciplines with the biggest potential. Ask what stems between where we are today and the mission we are on – the guiding star we decided on as part of the second principle (see the article ”Create a perpetual tailwind” about the mission).

You can use whatever processes for brainstorming you prefer. Again, I would recommend involving at least a few people with deep insight into the manufacturing processes in the company as well as people with the best insight into your customer’s needs, pains, and use of the products.

There are a few guiding principles that you should consider as part of this step. They help you determine how fast and how much you should decide to take on.

Focus on the core

It is essential to stay core. By that, I mean that you should focus on the core of what you do and upgrade that into a more sustainable version. You can find many companies that stick to their traditional product and then make some sustainability initiatives on insignificant products in the outskirts of the product portfolio. This is risky as you sooner or later will be called upon as not being trustworthy because you are marketing an insignificant green product line but maintain business as usual with your core top-selling products.

You have the most to gain and at the same time, you minimize risk when you develop better versions of the products you are known for. And when you find a way to leave a positive mark on the world with your core product, you will also increase your total positive impact.

It is not to say that you should jump right into changing your core product if you are at one of the basic levels but be sure that you set a direction that will take you to your core.

Start where you are

You can only build on where you are today. So, use the insight gained in the first step, and be sure to make that part of your initial journey.

Bandwidth for change

Ask yourself what state the organization is in today? How many change processes are already in motion? What is the workload and energy level like for the core people that absolutely must participate – including yourself? What other elements influence the state of the organization? Altogether I call this your bandwidth for change, and it is essential to match the bandwidth you have/can create with the speed of implementation and the size of the steps you decide to take. Set yourself up for success.

Decision criteria

You should now have an extensive list of potential initiatives and ideas. If you have had a good process, you are all quite engaged and can see significant opportunities to create a business with embedded environmental impact, now it is time to bring it all together and prioritize all the content you have created.

A simple yet powerful way to deal with this situation is to set up criteria for what constitutes a good next step and a good step further down the line.

Take a step back from it all and review how you scored yourself in terms of maturity earlier on and the answers to the question about bandwidth. Add to that the insight you have about your company, organization, and customers. And carve out the criteria that are important to you related to the results you want to achieve. Now filter all the ideas and initiatives from the brainstorming process through these criteria to get the shortlist that fits you best.

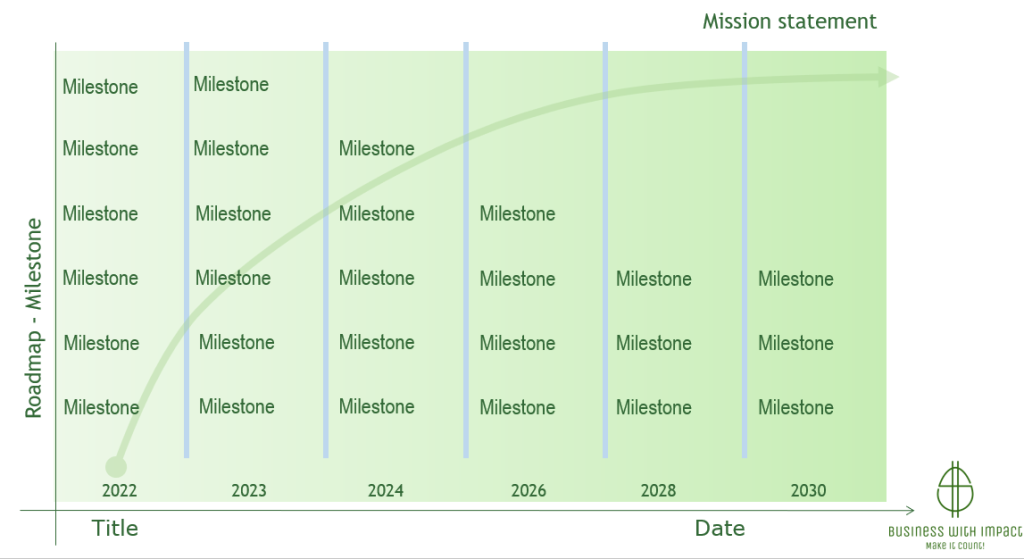

From here it is just a matter of putting them in a sequence and then you have your plan. I would recommend gathering it all in a high-level roadmap. A roadmap as in a graphic model they can use to get a one-pager for the whole journey with details on the first or two years and then gradually bigger and bigger chunks for the years ahead. You should end with a convincing map for bridging the gap between the present day and the mission.

It will be a valuable tool for you to communicate and create trust around the work you do.

It may seem like a lot of work but trust me, it will take your business to another level.